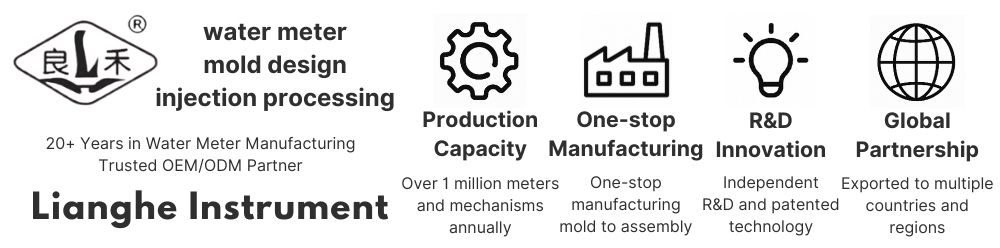

We provide end-to-end product realization—from design and mold build to mass production and assembly—with strong expertise in water meters and custom plastic parts.

Core Strengths

Design & DFM: wall thickness, ribs, snap-fits, ultrasonic welding

Tooling & Molding: optimized layouts, ABS/PC/PA materials, painting/printing/laser

Assembly: ultrasonic welding, functional tests, sub-assemblies

Quality: FAI, process control with full traceability; ISO 9001 certified

Flexible engagement: OEM/ODM, build-to-print, co-development

Proof Point

Smoke detector housing: delivered UL94 V-0 compliant design, mold optimization, and on-time mass production from T0/T1 trials to assembly.